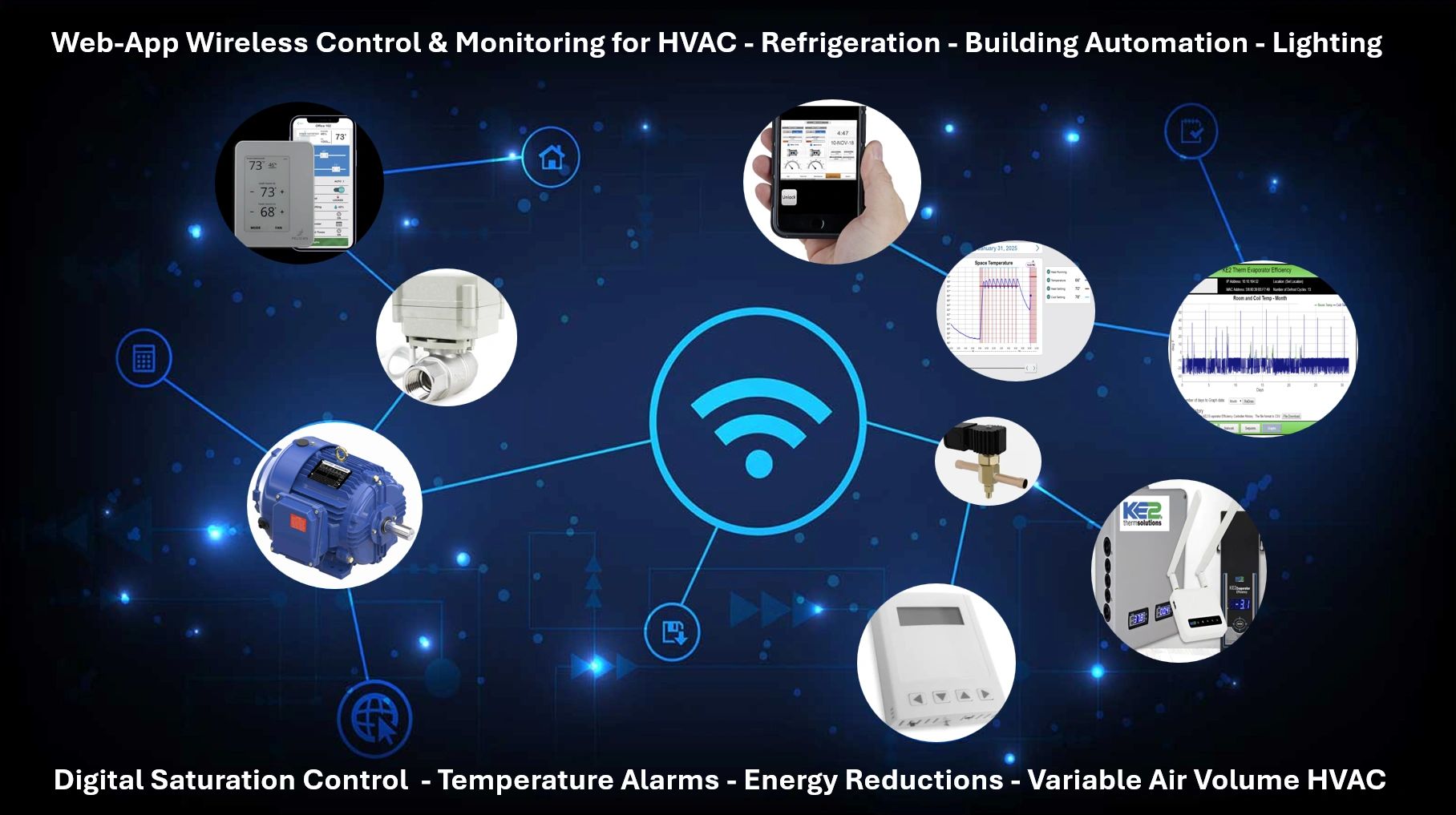

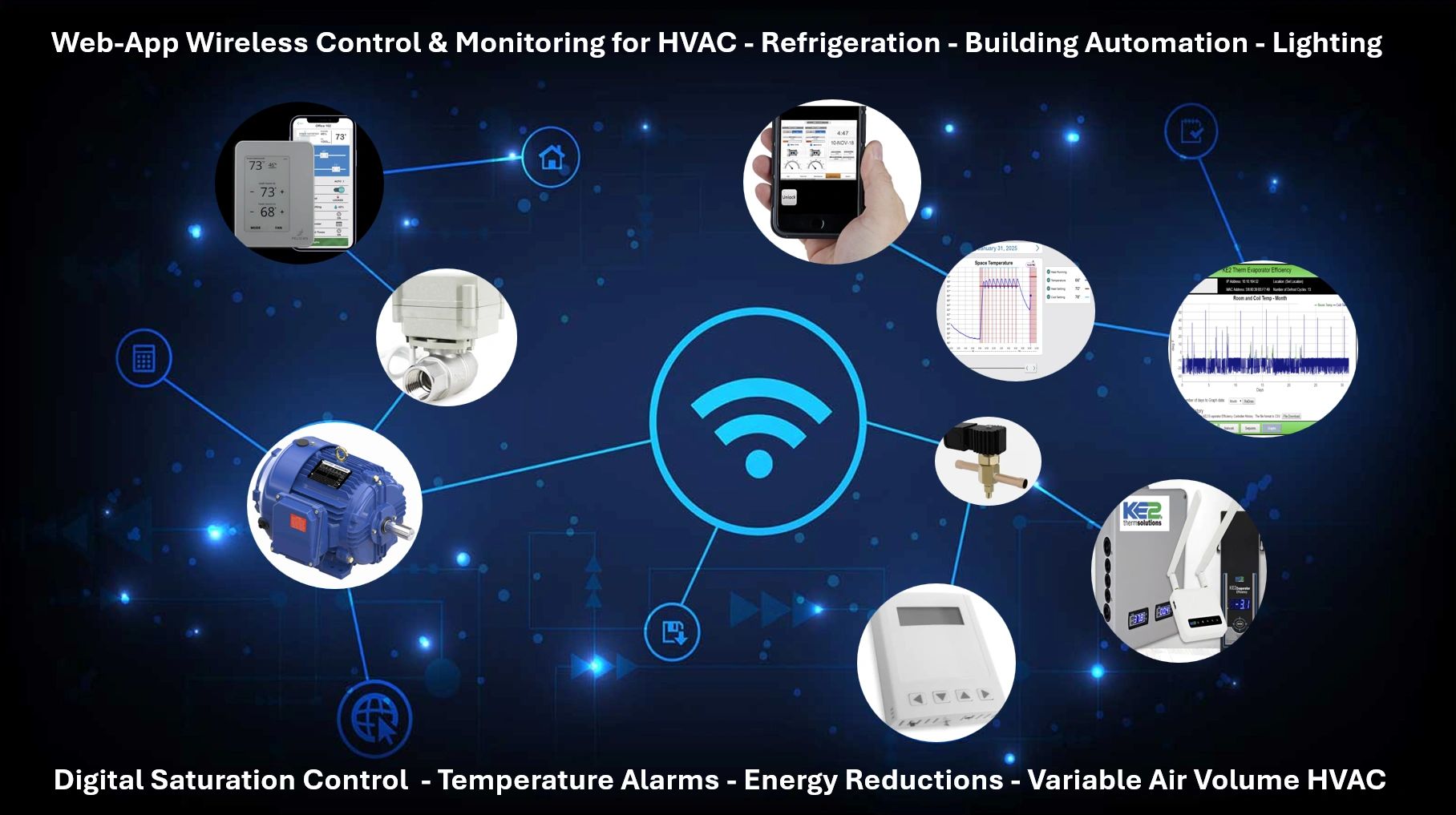

Remote Monitoring through Web-App Portals:

Through cellular connections and WiFi capabilities we can custom build just about any system to be Web-App monitored or controlled. Critical applications include walk-in freezers, refrigeration, HVAC, chemical processes, pumps/motors, ice machines, lighting, water heaters and boilers, valves, commercial kitchen applications with dishwashing machines, and much more.

Alarm portal systems can include temperature monitoring of any kind, water exposure to floors, ice build-up on roof edges, burst hoses, or pressure values all forwarded to Web-App portals on your phone, PC or tablet. Eliminate the need to physically go to your mechanical room or project site. Get real-time values updated every 8-10 seconds!

Web Access and Controls for HAVC / Refrigeration / Freezers

KE2Therm Refrigeration & Freezer Controls www.ke2therm.com

We are experts in refrigeration optimization as well as developers of digital saturation technology and are authorized dealers/installers of KE2Therm Solutions. Digital saturation control with intelligent defrosting can reduce refrigeration energy consumption by 50% or more.

Pelican Wireless Building Automation for HVAC:

Pelican Wireless

Real-Time Energy Data

Real-Time Energy Data

As integrators of the Pelican Wireless building automation systems, we deliver easy to use HVAC automation through wireless routers and gateways. Pelican Wireless is the most advanced building automation system ever developed providing variable volume control.

Real-Time Energy Data

Real-Time Energy Data

Real-Time Energy Data

Energy use through HVAC is constantly monitored and available through the Pelican Web-App portal. All run-times and cooling/heating cycles are tracked and daily HVAC energy use costs are calculated for you automatically.

Variable Volume HVAC

Real-Time Energy Data

Variable Volume HVAC

Variable volume HVAC can be retrofitted into most any existing HVAC system. Pelican Wireless controllers monitor the load required in the building and can vary the energy use only as needed saving wasted energy in unoccupied rooms. Learn more at: www.pelicanwireless.com

KE2Therm Refrigeration & Freezer Controls DSC Technology:

KE2Therm Refrigeration Controls

We are integrators of the KE2Therm refrigeration control package. Independent tests have proven energy reductions of up to 53% using smart adaptive defrosting and compressor cycling control. KE2Therm provides digital saturation control technology and greatly increases heat exchange efficiency.

Digital Saturation Technology

"Digital Saturation Control" or DSC improves the heat exchange rates by not just monitoring the cooler box, but the temperature of the coil surface. Additionally, when the coil surface is monitored and controlled, heat exchange rates jump by 16-20% giving you less needed run times of the compressor systems with reduced relative humidity.

Web-App Monitoring Temperatures

Web-App Monitoring Temperatures

The KE2Therm Web-App monitors all temperature history, defrosting cycles and notification alarms. Every 8-10 seconds the software is reporting values and will notify through text messaging or email if something is out of range saving thousands in potential food losses. Learn more at: www.ke2therm.com

Process Temperature Control & Real-Time Monitoring:

Meet the ARC I/O_12: A very powerful temperature process control & monitoring device.

No matter what you have, if it's tanks of milk, beer or any fluid, liquid or air-gas or compressed air, the I/O_12 is the only thermostat temperature process control based PLC with an LCD screen that can provide you with real-time values on display and on a web-app network at the same time giving you the ultimate control and data needed in critical operations.

The I/O_12 makes a perfect heat exchange process monitor/controller as all data can read real-time values of status or alarm. The I/O_12 can be programmed to fit most any application of heat transfer exchange, contact closure or temperature value control, and qualifies as M&V or "measurement and verification" under most electrical utility rebate programs. It functions as the ultimate watchdog for rooftop HVAC systems while monitoring refrigerant gas and air exchange temperatures. Diagnostics can be made from web-app remote with these provided values. The I/O_12 is an excellent add-on the the KE2Therm solution giving a more enhanced web-app enabled scope of the system operation.

Real-time values scroll across the screen every 3 seconds. The I/O_12 connects via Modbus to our headless HMI and SCADA system and provides 8 analog inputs/4 analog outputs with 5 dry contact relays (2A each-12/24vdc only). Alarms can be programmed and set to whatever values you need sent to text or email. The capabilities are endless when it comes to temperature monitoring or control with a plastic front cover engineered for your company logo or custom ID sticker. The I/O_12 is fully programmable using ladder logic software for just about any heat exchange process control.

Call us today to set up an engineered project plan and quote for installation.

Yaskawa Drives:

Reducing demand charges with soft starting and variable rate motors:

ARC is an authorized Yaskawa (VFD) dealer. Call us today for a quote or a commissioning/install.

Notable Installation Projects:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

The U.S. Army Corps water management building at the Jerry Litton Visitors Center, Smithville Lake was fitted with ARC technology to resolve heat load issues and prevented thousands of dollars spent replacing an under-sized rooftop HVAC unit.

Offutt AFB Omaha, NE:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

The team at ARC custom designed the server/data center HVAC system for the 55th Fighter Division Benny Davis flight training building when Liebert air-conditioning was not available during Covid. Air Force One landed twice while we were out there!

Arterra Event Center Lawrence, Kansas:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

Mercado Fresco Latin Grocer, State Ave. Kansas City KS:

ARC replaced all rooftop units with high efficiency variable volume HVAC. We were able to cut 10 tons of capacity from the building design and still maintain adequate comfort levels. Variable blower and compressor technology allows any facility to downsize the HVAC capacity.

Mercado Fresco Latin Grocer, State Ave. Kansas City KS:

Army Corps Building Jerry Litton Visitors Center Smithville, MO:

Mercado Fresco Latin Grocer, State Ave. Kansas City KS:

ARC was hired to install nearly 60 refrigeration and freezer systems of the KE2Therm Solutions for this new store build-out. 100% of all temperature control systems are using digital saturation technology for all meat and cheese, produce and freezer systems.

Marriott North Kansas City, MO Airport Location:

Marriott North Kansas City, MO Airport Location:

Marriott North Kansas City, MO Airport Location:

Pelican Hospitality was installed in both buildings at the North Kansas City, MO airport location. Over 400 rooms were fitted with the Pelican Wireless system. The hotel front desk now has total autonomy of all HVAC /PTAC systems in each room that are boiler/chilled water driven.

Oracle Park San Francisco, CA:

Marriott North Kansas City, MO Airport Location:

Marriott North Kansas City, MO Airport Location:

Pelican Wireless was the technology chosen for the indoor box seating climate control at the stadium. The engineers at Oracle saw the value in the Pelican Wireless HVAC climate control system and implemented it.

University of California Davis Campus:

Marriott North Kansas City, MO Airport Location:

Blue Origin Space HQ Facility Kent, WA:

UC Davis used their SWARM program to aggressively go after climate control energy reductions throughout the campus with a total energy reduction of 43% making it one of the most notable Pelican Wireless energy reduction projects yet.

Blue Origin Space HQ Facility Kent, WA:

Marriott North Kansas City, MO Airport Location:

Blue Origin Space HQ Facility Kent, WA:

Blue Origin chose the Pelican Wireless climate control system for the new HQ across the street from the original building. The 236,000 square foot facility sits on 31 acres and is one of the most energy efficient buildings ever built.

Our Partners:

Contact:

ARC: Advanced Rooftop Controls

11750 West 135th Street ste 1265, Overland Park, KS, USA

Advanced Rooftop Controls

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.